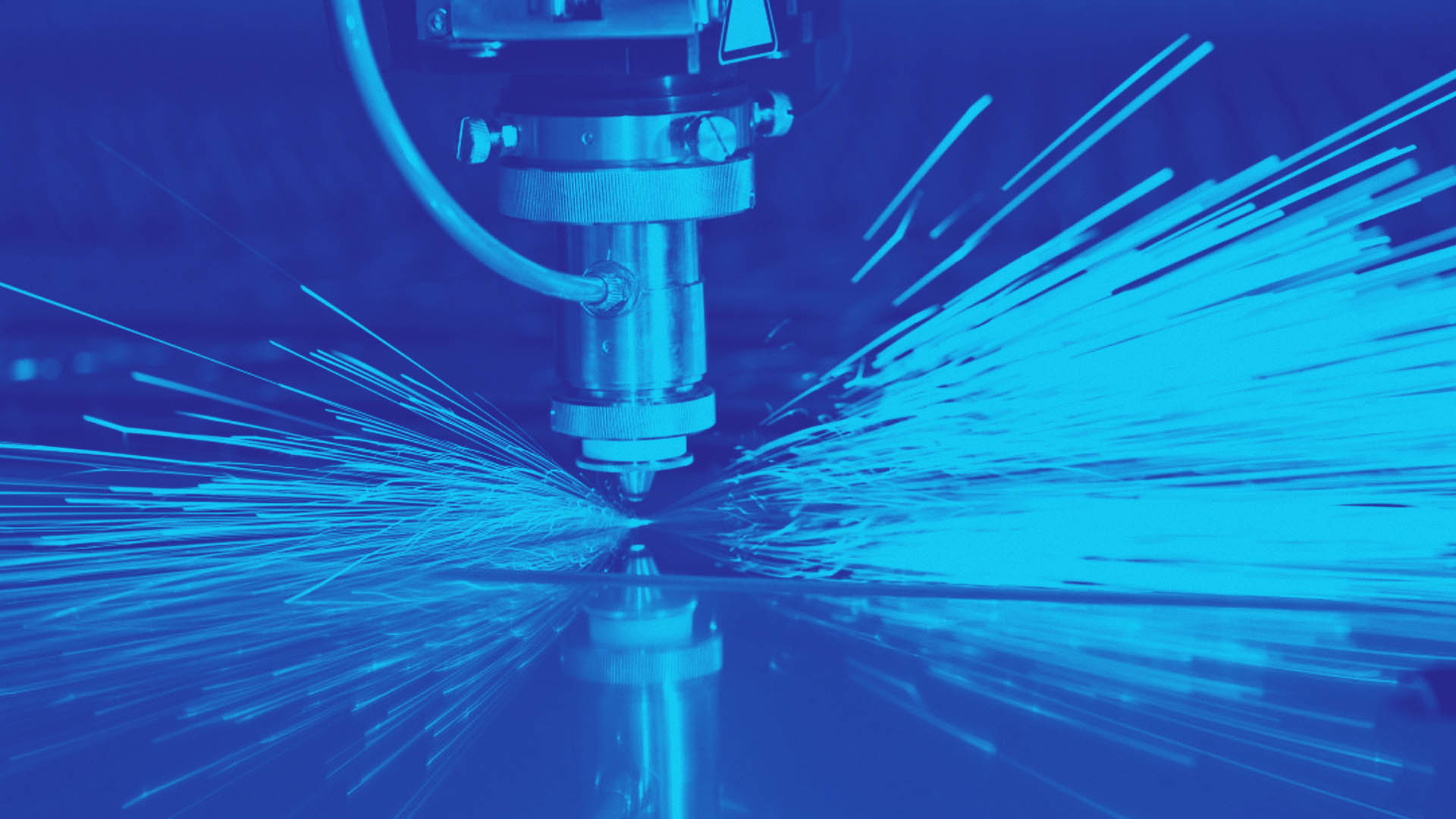

The quality of the goods you produce depends on the quality of your production process. At each step of the value chain, fixing a problem is approximately 10 times faster and cheaper than doing so in the next phase. Process quality management is essential to the continuous improvement of your production operations.

Bosch

www.bosch.com

A really fascinating article from Bosch. Whilst most organisations measure the quality of their products, very few measure the quality of the processes that create them.

The Rule of Ten states that it is not just rapid detection that is vital; the key is solving problems at the earliest points in the value chain. So for example, solving a simple inventory logging issue in Goods Inwards could create an on-going saving which is tenfold greater than the solving of an issue in the product assembly/manufacturing process.

The key point Bosch is making is that the Internet of Things might enable this process error detection to be automated. This could have a profound impact on manufacturers: moving the quality focus away from the detection of product errors to the prevention of process errors.